Northern College makes 3D printing more accessible with expanded state-of-the-art laboratory

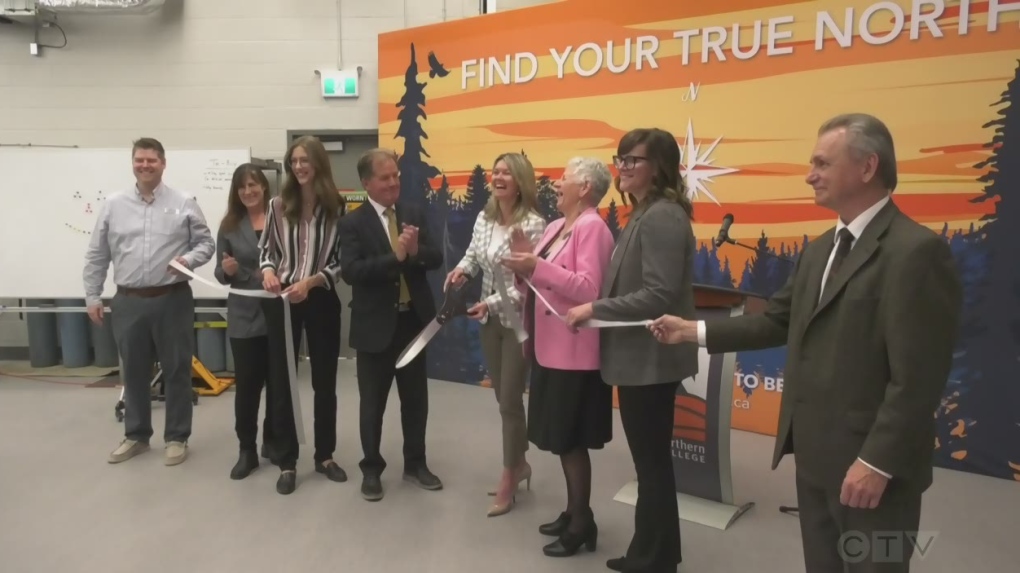

Northern College officials called it a "dream factory" for the north, as they unveiled the expansion of the school’s 3D printing lab to include every machine industries in the region need to develop new products.

If a company or a college student has an idea for a new product, they can design, print, prototype and pilot it using more than a dozen top-of-the-line machines in the 3D Futures Lab at Northern College in Timmins. June 12/23 (Sergio Arangio/CTV Northern Ontario)

If a company or a college student has an idea for a new product, they can design, print, prototype and pilot it using more than a dozen top-of-the-line machines in the 3D Futures Lab at Northern College in Timmins. June 12/23 (Sergio Arangio/CTV Northern Ontario)

If a company or a college student has an idea for a new product, they can design, print, prototype and pilot it using more than a dozen top-of-the-line machines in the 3D Futures Lab.

"There was definitely an industry need for a larger facility," said college president Audrey Penner.

"If you look around the room, you'll see there's a variety of printers, so there's also a need for printing with various materials."

Around $400,000 in federal funding allowed the college to expand its original printing lab which was considered a hidden gem in the region.

Housing a 3D scanner, computer modelling and around a dozen printing machines, the team of staff and students running the facility told CTV News it is capable of developing any simple or complex product with many in-demand materials.

"We can print plastics, thermal plastics, copper, stainless steel,” said Zain Bin Anser, a supply chain management student who took a summer job marketing the new lab to the region.

"We can even print bio-med materials, like a skull or a cranium, anything like that."

Bin Anser said he’ll be helping the college reach out to industries across the region to let them know about the lab and how it can assist them, gauge their needs and adapt the lab accordingly.

The lab lets a company rapidly bring a product from design to production in collaboration with the college.

- Download our app to get local alerts on your device

- Get the latest local updates sent right to your inbox

Sudbury-based product designer Stephen Podrucky said he finds it ground-breaking for the region as 3D printing is otherwise limited. Podrucky developed an augmented-reality fire extinguisher training system.

What’s not available locally needs to be outsourced south, he said, which can be expensive and time-consuming.

The expanded capability at the Timmins lab changes all of that, Podrucky said.

"There's nothing like this in northern Ontario,” he said.

"It's very rare to see this many different types of 3D printers and 3D printing technology in one space. You can kind of come here as a one-stop shop and get all the different types done."

With applications in mechanical and electrical engineering, health sciences and more, those running this lab are excited about the possibilities in various northern industries.

Mechanical engineering technology student Christian Smith said the lab lends itself to engineering fields that need to constantly test and tweak products.

Smith said he’s so excited about the possibilities this level of local 3D printing can bring to the region that he’s considering specializing in the technology after graduation.

"You can go design these models yourself and then send off to print and come back the next day and the thing's made,” he said.

"Just seeing your creations come to life, it's an amazing experience."

CTVNews.ca Top Stories

'Hell on earth': Ottawa rapper TwoTiime among Canadians displaced by L.A. fires

Ottawa rapper Khalid Omar, who performs under the name TwoTiime, was forced to evacuate his Calabasas condo as wildfires tore through the Los Angeles area this week, leaving the studio where he records in ruins.

16 dead, 16 missing as fire crews try to corral Los Angeles blazes before winds return this week

The death toll from the wildfires ravaging the Los Angeles area rose to 16 as crews battled to cut off the spreading blazes before potentially strong winds return that could push the flames toward some of the city's most famous landmarks.

Alberta premier Danielle Smith meets with Trump at impromptu Mar-a-Lago visit

Alberta premier Danielle Smith met with President-elect Donald Trump Saturday at Mar-a-Lago in Florida.

Are there U.S. military bases and American troops in Canada?

The U.S. military has more than 165,000 troops deployed in over 170 countries and territories, including Canada.

Costco Canada accused of overcharging online shoppers in class-action lawsuit

Perrier Attorneys says Costco charged more for items online than in-store, a practice known as “double ticketing,” which is banned under the Competition Act.

Meet Franklin, the rescued tortoise who spent the last three months in a B.C. fridge

Franklin the tortoise has been in a fridge for the past 15 weeks.

Teen's road test halted by stunt driving charge

A 17-year-old driver failed their road test before it even began after being stopped by police in a community safety zone.

'He was a genius': Family remembers man who died waiting for care in Winnipeg ER

The sister of a man who died waiting for care in the emergency department of Winnipeg’s Health Sciences Centre (HSC) is remembering her late brother as an intelligent person with a bold personality

Former PM Chretien says Liberal party must move back to 'radical centre'

As the Liberal party searches for a new leader, former prime minister Jean Chretien says it's time for the party to move back to the "radical centre" to help its electoral fortunes.