Vale unveils ambitious plans to boost nickel, copper production

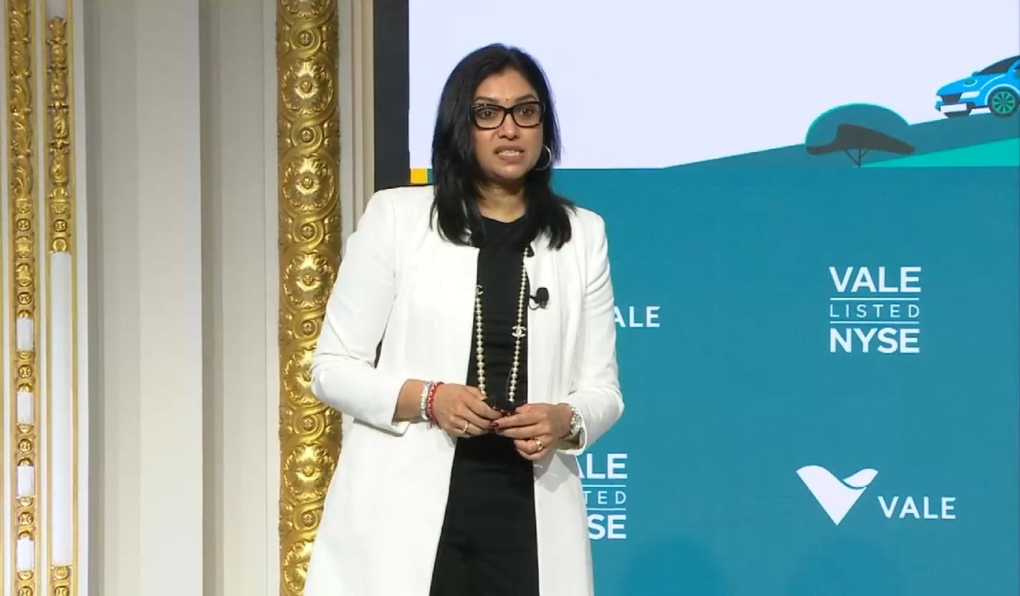

Deshnee Naidoo, the company’s executive vice-president of base metals, said Vale is a world leader in the production of energy transition materials. (Photo from video)

Deshnee Naidoo, the company’s executive vice-president of base metals, said Vale is a world leader in the production of energy transition materials. (Photo from video)

Vale Ltd. is committed to splitting off and growing its nickel and copper business, company officials told investors this week.

Speaking in New York on Wednesday, CEO Eduardo Bartolomeo said the company’s nickel assets in the north and copper assets in the south uniquely position Vale to supply the metals needed for decarbonisation “that the energy revolution is bringing to us.”

“When we arrived and acquired Inco in 2006 … we acquired the best sulphide assets there are in the Sudbury Basin,” Bartolomeo said.

The company is known as primarily an iron producer, but officials said this week that they are putting a new emphasis on developing base metals needed for electric vehicles.

Deshnee Naidoo, the company’s executive vice-president of base metals, said Vale is a world leader in the production of “energy transition materials.”

“This is nickel and copper’s time,” Naidoo said. “It’s all about EV growth.”

Vale expects tight nickel markets in the medium term, with supply shortages a possibility.

“All of this translates into a bright future for nickel and copper,” she said.

“We are uniquely placed to deliver on the demand growth.”

Vale can produce the metals with a low carbon footprint, she added.

“For base metals, more than 90 per cent of our electricity comes from renewable sources.”

And the plant they are building in Quebec can process 25,000 tonnes nickel into 110,000 tons of factory grade nickel sulphate.

“That will go to GM,” Naidoo said, a reference to the company’s recent deal with the auto giant.

She said a new operations centre in Sudbury is a great example of how the company is committed to improving safety and production.

The integrated remote operations centre connects operations at Creighton Mine, Coleman Mine and Totten Mine. Longer term, she said it will oversee all Vale’s mines in Canada, which include operations in Manitoba and Newfoundland.

The centre allows operators to monitor activity, as well as remote controlled operations that have already helped boost production by 10 per cent this year at Coleman and Creighton.

It includes 45 kilometres of underground communication cables, the biggest underground comms site in the world.

Watch the full presentation here.

CTVNews.ca Top Stories

Budget 2024 'likely to be the worst' in decades, former BoC governor says

Without having seen it, former Bank of Canada governor David Dodge believes that Tuesday's 2024 federal budget from Deputy Prime Minister and Finance Minister Chrystia Freeland is 'likely to be the worst budget' in decades.

What's at stake for Canada after Iran's unprecedented attack on Israel

Following the Iranian missile and drone strikes against Israel over the weekend, Canada should take the threat of Iran and potential escalation of the conflict seriously, one global affairs analyst says.

Former B.C. school trustee's 'strip-tease artist' remark was defamatory, judge rules

A controversial former school trustee from B.C.'s Fraser Valley who described a political rival as a "strip-tease artist" during an election campaign has been ordered to pay her $45,000 for defamation.

'A sense of urgency': Sask. man accused of abducting daughter calls himself to the stand during trial

Michael Gordon Jackson, the man on trial after being charged with contravention of a custody order for allegedly abducting his daughter in late 2021 to prevent her from getting a COVID-19 vaccine, called himself to the stand Monday.

Kingston, Ont.'s Aaliyah Edwards drafted into WNBA

After four years at the University of Connecticut, Edwards was selected sixth overall by the Washington Mystics in the WNBA draft Monday night.

NASA confirms mystery object that crashed through roof of Florida home came from space station

NASA confirmed Monday that a mystery object that crashed through the roof of a Florida home last month was a chunk of space junk from equipment discarded at the International Space Station.

A knife attack in Australia against a bishop and a priest is being treated as terrorism, police say

Horrified worshippers watched online and in person as a bishop was stabbed at the altar during a church service in Sydney on Sunday evening.

Body of 14-year-old boy pulled from Lake Ontario, police say he drowned while swimming

The body of a 14-year-old boy has been pulled from Lake Ontario after police say he drowned while swimming near Ashbridges Bay Park on Sunday night.

'Rust' armourer gets 18 months in prison for fatal shooting by Alec Baldwin on set

A movie weapons supervisor was sentenced to 18 months in prison in the fatal shooting of a cinematographer by Alec Baldwin on the set of 'Rust.'